Toybaru

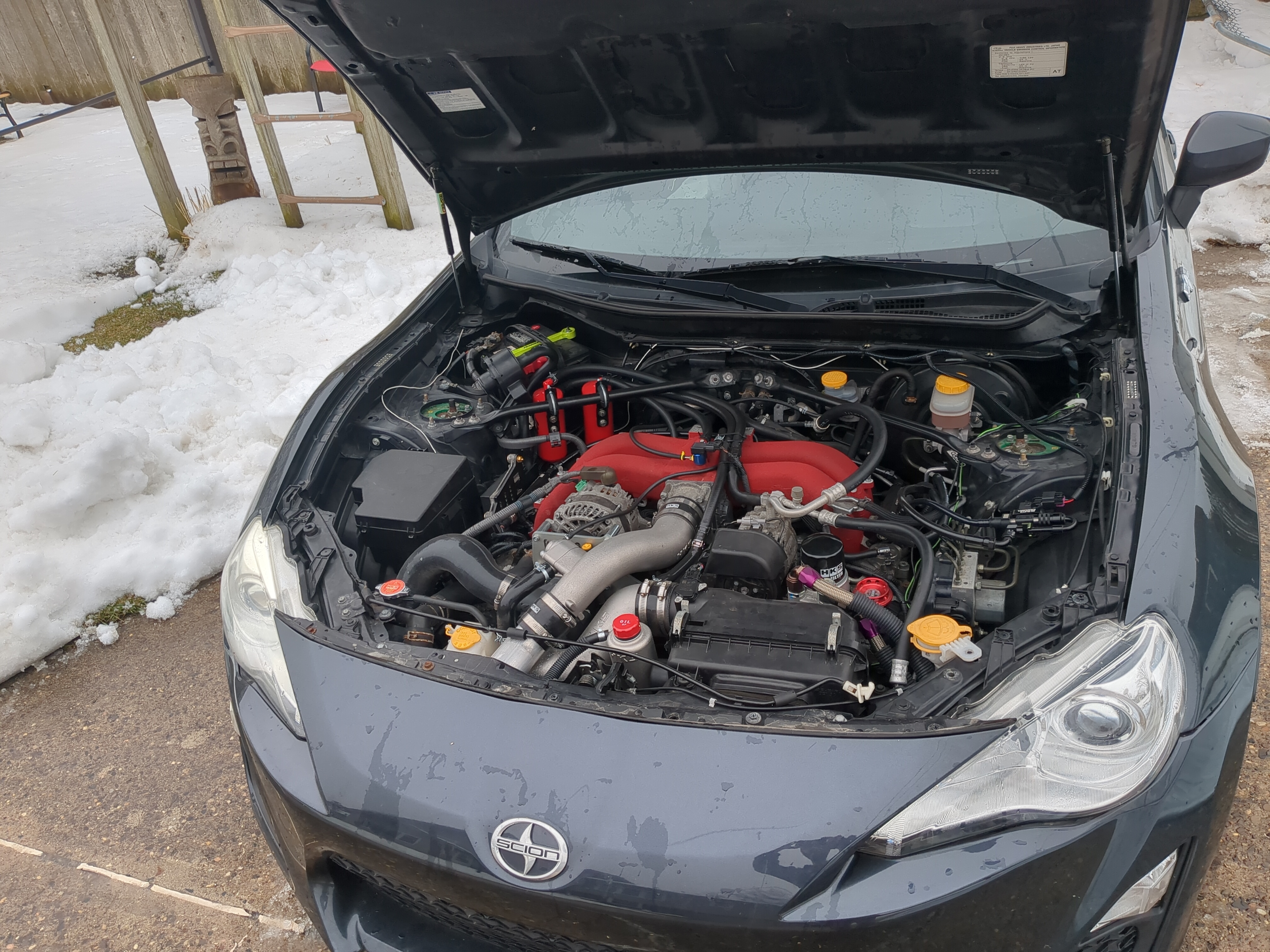

Every car enthusiast has a story. Mine begins in 2015 with a nearly new Scion FRS. With only 38,000 miles on the clock, it was a perfect blank canvas. For me, it became more than just a daily driver; it was a therapy project, a reflection of my own journey, and a challenge to see just how far I could push a humble “Toyobaru” platform. The goal? To build a car that could punch well above its weight class.

The Spec Sheet

| Specification | Stock | Modified |

|---|---|---|

| Weight | ~2,800 lbs | ~2,850 lbs |

| Horsepower | ~200 hp | ~320 hp |

| Torque | ~151 lb-ft | ~220 lb-ft |

| Balance | 53% Front / 47% Rear | ~54% Front / 46% Rear |

The Build: A Methodical Transformation

This wasn’t a weekend project. It was a slow, deliberate process of upgrading and refining, turning a capable sports coupe into a finely tuned performance machine.

| Part | Description |

|---|---|

| Supercharger | HKS GT2 Supercharger Pro V3 |

| Injectors | Injector Dynamics 1050x |

| E85 Sensor | Visconti Flex Fuel Kit |

| Oil Cooler | HKS S-Type Oil Cooler |

| Intake Manifold | Subaru STi Aluminum Intake Manifold |

| Gauges | GlowShift Triple Gauge Kit |

Foundation: Brakes and Maintenance

Before adding power, you have to ensure you can control it. After years of daily driving in the corrosive environments of Chicago and Montreal, the car needed some attention. The brakes were shot, and a rear wheel bearing was failing. This is where I learned a hard lesson about wheel spacers and dissimilar metal corrosion. The spacers had effectively welded themselves to the hubs, requiring me to drill them out just to get them off.

With the hubs repaired, I installed a fresh set of brakes, a crucial first step before turning up the power.

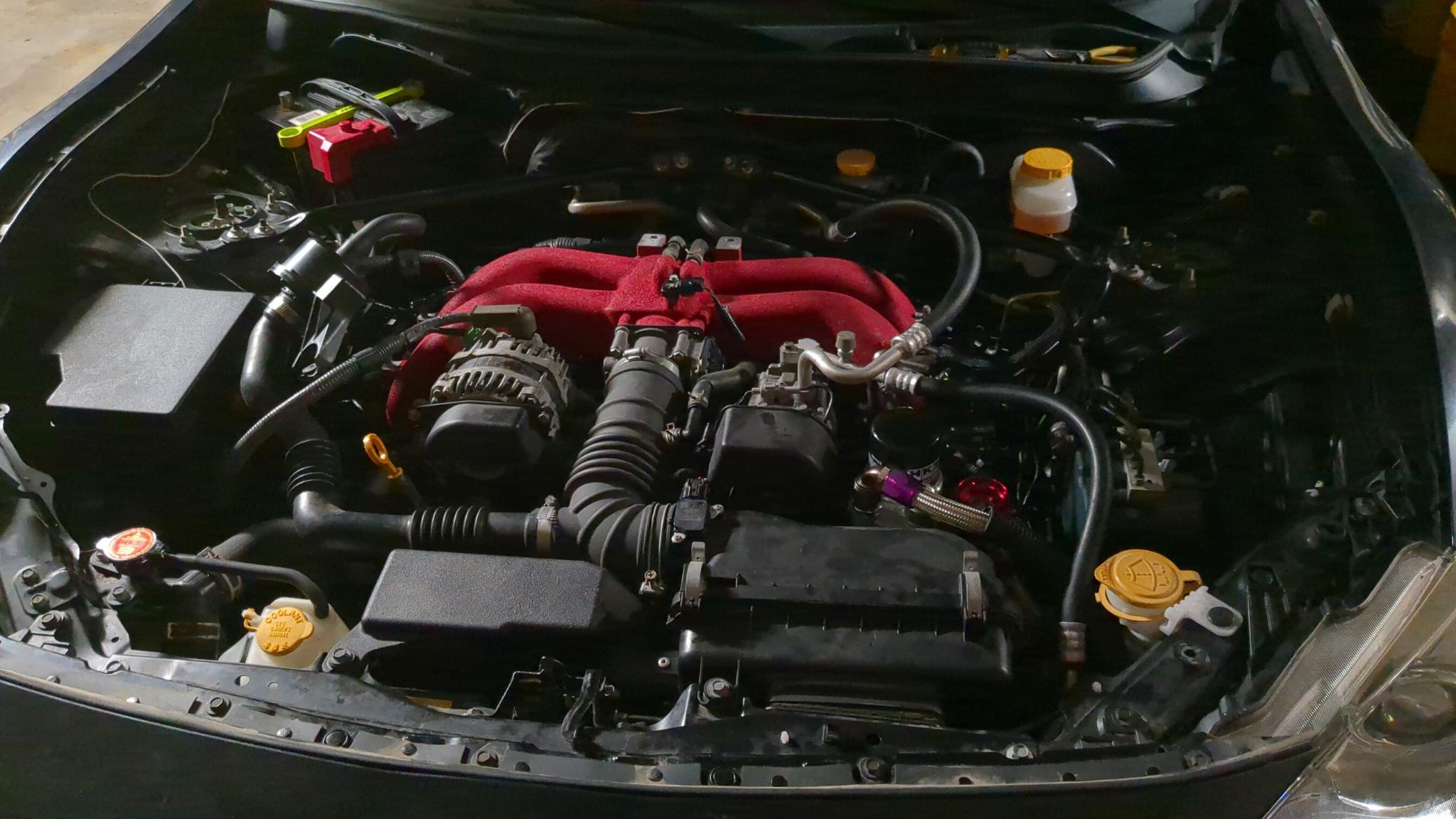

The Oil System: The Heart of the Build

The first major performance upgrade was an HKS oil cooler. This was a cornerstone of the build for several reasons. It increases engine longevity under stress, it’s a prerequisite for forced induction, and it gave me an excuse to install a set of triple gauges to monitor oil pressure and temperature. It’s a nod to the first Fast and Furious movie, but more importantly, it provides peace of mind when you’re pushing an engine to its limits.

Intake and Fuel: Preparing for Boost

The real power gains would come from forced induction, but first, the engine needed to breathe and drink. I sourced a lightweight aluminum intake manifold from an STi and paired it with Radium fuel rails and massive Injector Dynamics 1050x fuel injectors. These injectors more than double the stock fuel flow, a critical upgrade for the next step: E85.

Ethanol has a higher octane rating than gasoline, meaning it can withstand more compression before detonating. This makes it the perfect fuel for a high-compression, forced-induction engine.

Forced Induction: The HKS Supercharger

This was the moment all the other modifications had been leading up to. The HKS supercharger is the key that unlocks the engine’s true potential. The principle is simple: more air + more fuel = more power. The supercharger forces more air into the engine, and the upgraded fuel system delivers the E85 to match. The result is a jump from the stock 200 horsepower to a much more respectable 320 horsepower.

The End of an Era

Every project has its end. After years of faithful service as a daily driver and a weekend warrior, the journey with this car came to an unfortunate close in the spring of 2024. But the lessons learned and the thrill of building something with my own hands will stay with me forever. It was more than just a car; it was a rolling testament to the joy of engineering and the pursuit of performance.